Tornado Antriebstechnik with

turnstacker premium 25/35

Tornado Antriebstechnik with

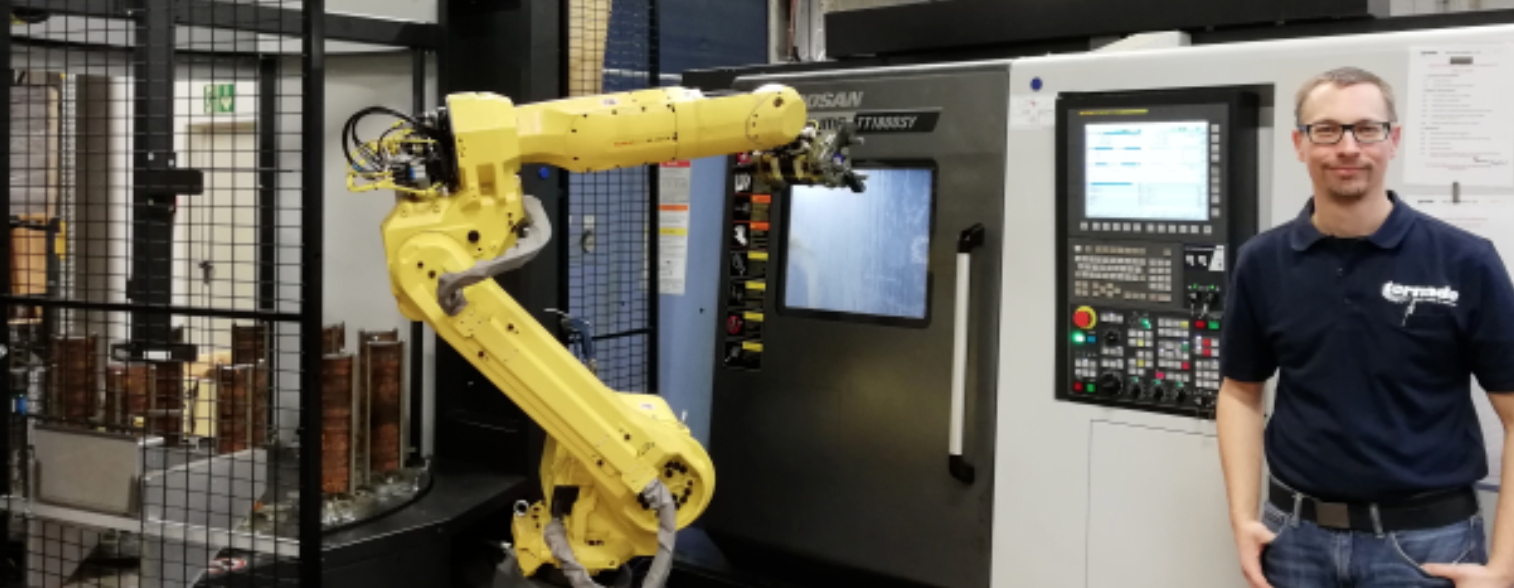

turnstacker premium 25/35 "We achieve a spindle efficiency of 92% thanks to the HALTER LoadAssistant."

Martin Richter, Project Manager, Tornado Antriebstechnik

“We want more production capacity. That is why all new machines that we use for machining larger series are automated,” says Martin Richter, assistant technical management at Tornado Antriebstechnik in Berlin. The manufacturer of both standard and customer-specific drives makes many components in-house. To keep up with the growth of orders, they invested in three new CNC machines. Each of them has a HALTER LoadAssistant robot cell. “This allows us to make optimal use of our machines. To give an example: our DN Solutions TT1800SY recently achieved 92% spindle efficiency in a month’s time.”

The good functionality, the price-quality ratio and the fast availability were decisive factors in choosing HALTER. Martin Richter: “Learning to program and operate takes little time. And the robot cells require little maintenance.”

Tornado Antriebstechniek wants to further modernize and expand the machinery in the near future. Automation is part of this. “And then we will definitely include the HALTER LoadAssistant in our selection again.”

Producing parts for drive systems

120 employees

Berlin

Germany

HALTER CNC Automation GmbH

Gewerbering 7

47661 Issum

Germany

T: +49 2835 955 3990

info@haltercnc.com

VAT ID: DE326335222

Company ID: HRB 16121

HALTER CNC Robotics LLC

21995 Fillmore Road

Cascade, Iowa 52033

United States

T: +1 800 314 8261

info@haltercncrobotics.com

VAT ID: US473961908